We provide Boron Carbide(B4C), Silicon Carbide(SiC), Tungsten Carbide(TC) material sandblasting nozzles.

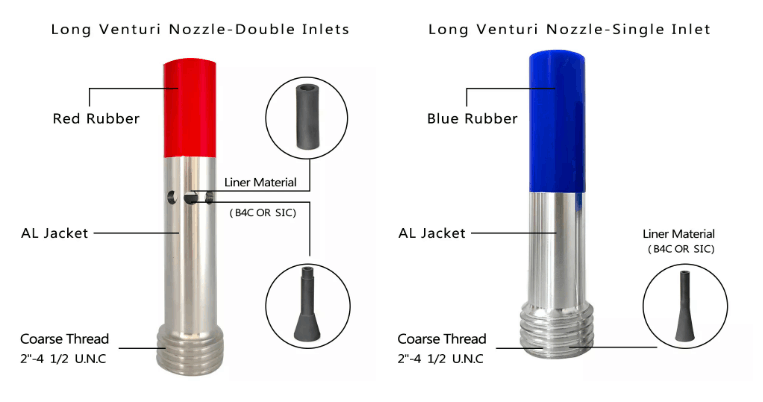

Venturi Nozzles

Gas dynamic of single venturi nozzles is better than straight-hole nozzle, the vortex is improved or ceased to exist, greatly reduced the pressure loss in the same pressure conditions. Abrasive exports increased to more than double the speed, efficiency than the straight-hole nozzle to increase 15%~40%, 20% lower abrasive consumption.

Double venturi nozzles offers a 35% larger blast pattern than a standard long venture with only a very slight loss in abrasive velocity. Designed to be used on jobs where medium cutting action is required with a more even dIspersion of abrasive throughout the larger blast pattern. Excellent for plastic or agricultural abrasives.

Straight Bore Nozzles

1.Density:2.48g/cm3

2.Outter dia:6-110mm; Inner dia:3.2-90mm

3.Length:20-330mm

Straight hole nozzle has the characteristics of a simple structure, only with the converging section and straight section. However, this kind of nozzle also has the problem of the vortex at the entry area, high pressure loss and low outlet velocity, as lower as 50% of Venturi nozzle.

Straight hole nozzle is usurally used withinthe sand-blasting machines,which have low sprayintensity and narrow closed struture.

Various shapes and sizes of boron carbide nozzles are available.

Water Induction Nozzles

Water Induction Nozzles a simple solution for high production, which developed on the foundation of Double Venturi Nozzles. wet abrasive blasting that can be used with your existing pressure blast equipment. Requiring only 3/4 to 6 quarts per minute, water consumption is lower than most other wet blast options.

Angle Nozzles

Angle nozzles is ideal for blasting hard to reach areas such as the interior of pipes, bulkheads in ships, bridge lattice, and other tight spaces. Choose between one or three outlets for up to 360 degrees of surface area coverage. HB Angle Nozzles are available in 45°, 90°, and 135°.

Bending Blasting Nozzles

The curved nozzle, known as the banana nozzle, is designed to precisely blast into the tight or hard to reach areas, such as some corners within the flange back and pipeline. 40° to 45° curves are the common range for the curved nozzles. The curved nozzles are made of boron carbide or tungsten carbide.

Nozzle Liners

Various nozzles liner available, including Material: B4C, TC & SIC